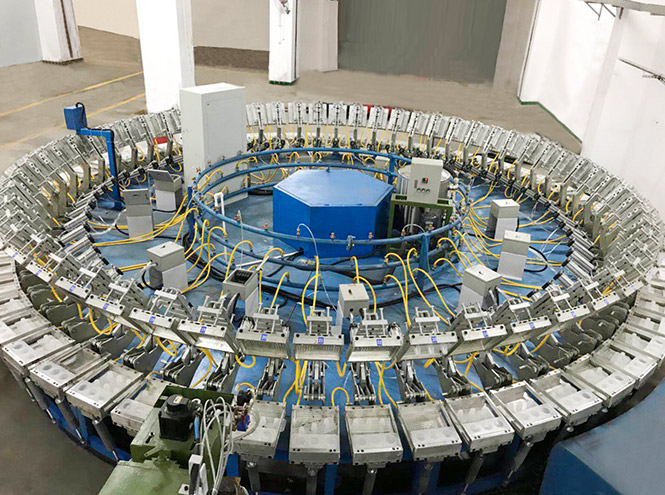

PU Matrix Block Foaming Machine with Automatic Production Line

|

Main Technical Parameters

|

||||

|

Model No

|

Out put

(g/s) |

Material Tank Volume

(L) |

Mixing Ratio

(P:I) |

Total Power

(KW) |

|

LZ-905A

|

5-15

|

200

|

100:35-85

|

12

|

|

LZ-905B

|

30-100

|

200

|

100:35-85

|

12

|

|

LZ-905C

|

50-150

|

200

|

100:35-85

|

12

|

Welcome to call 137-5172-5551, Consulting and ordering

Description

Product Features

· Imported components are used for the metering pump and electrical components, greatly enhancing equipment running reliability and service life.

· New generation programmable controllers are provided with more comprehensive and practical functions, making the machine more convenient to operate; a needle valve type never worn injector is used to further ensure product quality.

· The moulds using pneumatic coling, to reduce the costs and labor, also reduce the waste caused by the operation.

· The mold using the circulating water heating method, it can save 3/2 energy as the traditional way, in this way, the temperature of the mold can control within ± 2 ℃.

· New generation programmable controllers are provided with more comprehensive and practical functions, making the machine more convenient to operate; a needle valve type never worn injector is used to further ensure product quality.

· The moulds using pneumatic coling, to reduce the costs and labor, also reduce the waste caused by the operation.

· The mold using the circulating water heating method, it can save 3/2 energy as the traditional way, in this way, the temperature of the mold can control within ± 2 ℃.

|

Main Technical Parameters

|

||||

|

Model No

|

Diameter Size)

(m) |

Stations

|

Installation dimensions

(m) |

Total Power

(KW) |

|

LZ-605A

|

5/8

|

48

|

7×10×0.65

|

22

|

|

LZ-605B

|

6/10

|

60

|

8×11×2.1

|

22

|

|

LZ-605C

|

8/13

|

80

|

9×12×2.1

|

22

|

Application Scope